Aluminum Metal Casting: Advancements, Applications, and Environmental Considerations

Aluminum metal casting is a vital process that plays a significant role in various industries. This article explores the world of aluminum metal casting, its process, types, advancements, quality control measures, environmental considerations, and real-world applications. By delving into these aspects, we can gain a comprehensive understanding of the importance and potential of aluminum metal casting.

I. Introduction to Aluminum Metal Casting

Aluminum metal casting involves the shaping of aluminum alloys into complex and intricate forms through a casting process. It is a versatile and cost-effective method widely employed in industries such as automotive, aerospace, consumer goods, and more. The ability of aluminum to be molded into various shapes while maintaining its strength makes it a preferred choice for numerous applications.

II. Aluminum Casting Process

The aluminum casting process comprises several key steps, starting with the melting and preparation of aluminum. Once the aluminum is molten, a mold is designed and prepared, taking into account the desired shape and intricacies of the final product. The molten aluminum is then poured into the mold, where it solidifies and takes the form of the mold cavity. Finally, the casting is removed from the mold and undergoes finishing processes to achieve the desired surface quality and dimensions.

III. Types of Aluminum Casting

- Sand Casting: Sand casting is one of the most common and versatile methods for aluminum casting. It involves creating a mold using a mixture of sand and binders. Sand casting offers flexibility in terms of size, shape, and complexity, making it suitable for both small and large-scale production.

- Die Casting: Die casting utilizes reusable molds, called dies, to create intricate aluminum parts with high dimensional accuracy and excellent surface finish. It is a highly efficient and cost-effective method suitable for mass production.

- Investment Casting: Investment casting, also known as lost-wax casting, utilizes a wax pattern that is coated with a ceramic shell. Once the shell hardens, the wax is melted out, leaving behind a cavity. Molten aluminum is then poured into the cavity, creating the final casting. Investment casting is renowned for its ability to produce intricate and complex shapes.

IV. Advancements and Innovations in Aluminum Metal Casting

Continual advancements in aluminum metal casting have paved the way for improved techniques and alloys. Some notable advancements include:

- Low-pressure Casting: Low-pressure casting involves applying low pressure to the molten aluminum during the casting process, ensuring a more controlled and consistent fill of the mold. This method reduces defects and improves the overall quality of the castings.

- Vacuum Casting: Vacuum casting removes air and gases from the mold cavity before pouring the molten aluminum, resulting in higher density and improved surface finish. It is particularly beneficial for producing high-quality, defect-free castings.

- Squeeze Casting: Squeeze casting involves applying pressure to the solidifying metal, enhancing the mechanical properties of the casting. This method is often used to manufacture parts that require superior strength and durability.

V. Quality Control and Inspection in Aluminum Metal Casting

Ensuring the quality of aluminum castings is essential to meet industry standards and customer expectations. Quality control measures include visual inspection, non-destructive testing, and dimensional measurement. Detecting and rectifying defects, such as porosity, inclusions, and dimensional variations, ensures the production of high-quality castings.

VI. Environmental Considerations in Aluminum Metal Casting

- Energy Consumption and Emissions: Aluminum metal casting processes consume significant energy. However, advancements in energy-efficient furnaces and process optimization techniques help reduce energy consumption and associated emissions, contributing to a greener manufacturing approach.

- Recycling and Sustainability: Aluminum is a highly recyclable material, with recycling rates exceeding 90%. The recycling of aluminum reduces the need for primary aluminum production, conserves natural resources, and minimizes environmental impact. By embracing recycling practices and using recycled aluminum in the casting process, manufacturers can contribute to a more sustainable and circular economy.

- Waste Management and Pollution Control: Proper waste management and pollution control measures are crucial in aluminum metal casting. Implementing efficient filtration systems, controlling emissions, and adopting responsible waste disposal practices help mitigate the environmental footprint of the casting process.

VII. Case Studies and Examples

- Application of Aluminum Metal Casting in the Automotive Industry: Aluminum castings find extensive use in the automotive industry, where weight reduction and durability are critical. Engine blocks, cylinder heads, transmission cases, and suspension components are some examples of aluminum castings used in automobiles. Aluminum’s lightweight nature and excellent heat transfer properties contribute to fuel efficiency and improved performance.

- Aluminum Casting in Aerospace Applications: The aerospace industry relies on aluminum castings for various components, including aircraft engine parts, structural elements, and aerospace tooling. Aluminum’s high strength-to-weight ratio and corrosion resistance make it ideal for aerospace applications where stringent performance requirements must be met.

- Aluminum Casting for Consumer Goods: Aluminum castings are widely used in the production of consumer goods such as cookware, furniture, and electronic enclosures. The versatility of aluminum allows for intricate and aesthetically pleasing designs while maintaining durability and heat conductivity.

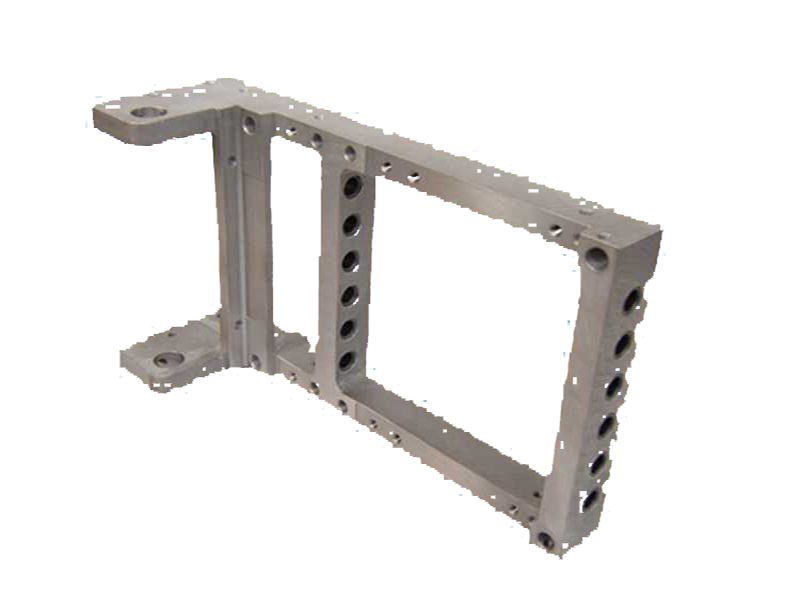

Looking for a reliable and efficient aluminum die casting manufacturer? Look no further than CNM China die casting company! With over 18 years of experience, we specialize in die casting aluminum, magnesium die casting, and zinc die casting products, as well as machining parts, metal stamping, and plastic molds making.

Our advanced equipment and machinery ensure that we produce the highest quality and cost-effective die casting solutions. From flow meter housing and valves to lighting fixture parts, automobile parts, and decorative hardware, we can manufacture a wide range of products to meet your needs.

Our team of professional engineers and mold designers are always ready to take on new projects. Simply send us your 3D part design in STP or IGS format, and we will get back to you within 24 hours with pricing details.

Exporting various aluminum die casting, zinc die casting, and magnesium casting products, CNM Tech is the go-to manufacturer for all your die casting needs. Contact us now to experience our exceptional services and premium quality products at affordable prices!

VIII. Conclusion

Aluminum metal casting is a fundamental process that empowers industries with the ability to create complex shapes and structures from this versatile material. With advancements in casting techniques, the development of advanced alloys, and a focus on quality control and environmental considerations, the future of aluminum casting looks promising. By embracing sustainable practices, manufacturers can contribute to a greener and more efficient casting industry. As we continue to explore new applications and push the boundaries of aluminum metal casting, its importance and potential will only continue to grow in the global manufacturing landscape.

Remember, if you are in need of high-quality aluminum castings for your specific industry or application, it is essential to partner with a reputable casting company that has the expertise and resources to deliver superior products.

Recent Comments